Advanced PPD Printer for Industrial Applications

WIPRO 3D F300-2

Industrial Grade 3D Printer

Key Features

- Prepare – Load – Print

- Wi-Fi Connectivity

- Kinematic 3 Point Bed Leveling

- Remote Monitoring & Control

- Sensor for Automatic Calibration

Ease of Use

- Touch Screen Console

- Filament Runout Notification

- Live Feed Camera

- Automatic Shutdown

- Cloud Connect Feature

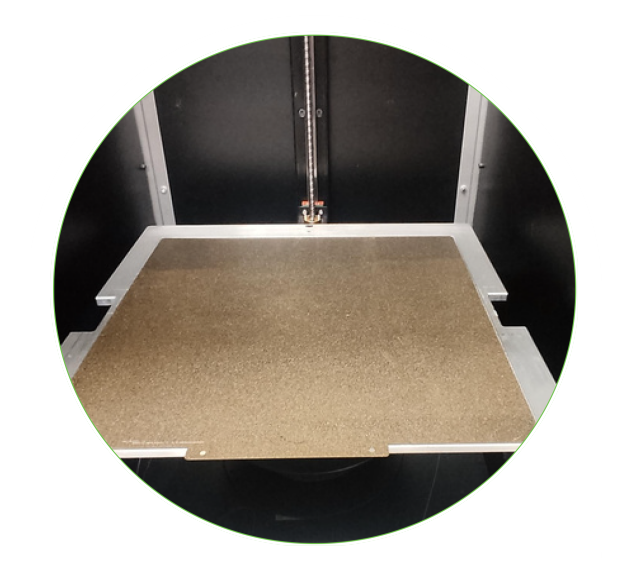

Build Chamber

- 300 x 300 x 300 mm Build Volume

- Heated Aluminium platform

- Dual Filtration System

- Temperature Controlled Build Chamber

Distinct Featured

Smart Runout Sensor

Magnetically Latched Base Plate for Improved Performance

Dual Filtration System

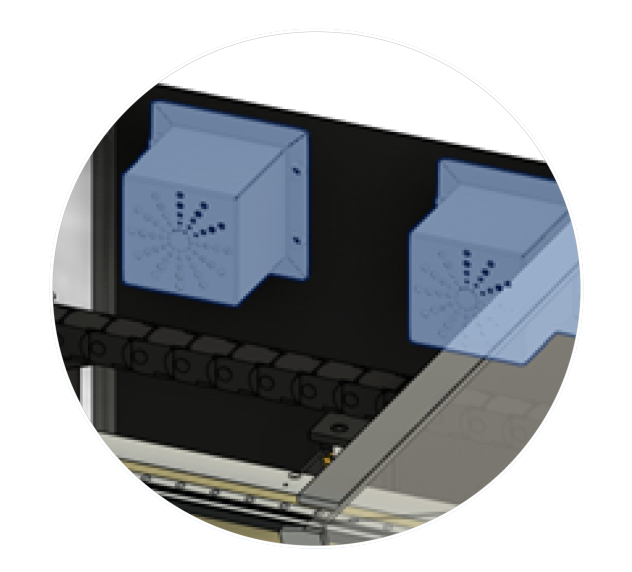

Hotend

- Dual Nozzle

- Advanced Nozzle Cleaning System

- Hotend Lifting Mechanism

Operating Temp.

- Platform Temp. up to 120 °C

- Hotend Temp. up to 310°C

Materials

- Wide Material Range And Compatible With External Filaments

- 1.75 mm dia Filament

- Soluble Supports

- Print head for printing metal fused filaments

Quality

- Warm Filament Storage Bay

- All Metal Body

- Bowden Type Extrusion

Technical Specifications

Device

| Printing Technology | Fused Filament Fabrication (FFF) |

| Print Head | Dual Nozzle |

| Layer Resolution | 100-400 micron |

| Build Plate | Heated Aluminium Platform with Flexible Build Plate, held in place with High-Performance Magnets. |

| Build Volume | 300 x 300 x 300 mm (11.8 x 11.8 x 11.8 in) |

| Material Container | Inbuilt Material Dispensing Unit with Smart Filament Runout Sensor & Humidity Monitoring |

| Material Diameter | 1.75 mm (0.069 in) |

| Nozzle Diameter | 0.4 mm and other standard 0.6mm diameter |

| X, Y, Z accuracy | 10 microns in all |

| Print Head Travel | Up to 200 mm/s |

| Nozzle Heat Up Time | 1 min |

| Build Plate Heat Up Time | <4 min |

| Average Operating Sound | < 50 dB |

| File Transfer | USB, LAN, Wi-Fi |

| Build Plate Leveling | Kinematic 3 Point Platform Balancing with Intelligent Mesh Levelling System |

| Support | Soluble support printable with the second print head |

| Extruder | Dual Nozzle with In Situ Nozzle Lifting System |

| Hotend Cooling System | Two axial fans cooling the hotend One radial fan cooling the print |

| Hotend | E3D V6 Hotend |

| Platform | PEI Coated Flexible Spring Steel (Heated and Magnetically Latched) |

| Material Endstop | Mechanical |

| Connectivity | Wi-Fi, Ethernet, USB |

| Scanner type | Handheld |

| Operating system | Linux |

| Processor | Quad Core Cortex-A72 |

| Touchscreen | 7″ Capacitive |

| Camera | 5 MP Wide-angle Camera 130° FOV |

| Materials Compatible | PLA, ABS, ASA, HIPS, PET-G, Nylon (PA6, Materials Compatible PA12, PA6-CF, PAHT-CF), TPU90A, TPU95A, PC, PC-FR, ESD, FLEX, GLASS, different composites, and compatible with metallic filaments like 316 and 17-4PH and more |

Software

| Software Bundle | Simplify 3D or Other Slicing Softwares |

| Supported File Types | .stl, .obj, .3mf, .ply |

| Supported OS | Mac OS X / Windows 7 & Later / Linux |

| Features | All basic and advanced features of slicing, build preparation, wall thickness analysis, linear dimensional data, various infill density, and ONE CLICK PRINT feature etc. |

Printing

| Technology | (FFF) Fused Filament Fabrication |

| Layer Height | 0.2 mm (Default) |

| Wall Thickness | 0.4 mm (Minimum) |

| Platform Levelling | Three Point Levelling |

| Modes | Variable Speed Mode |

Temperature

| Max Printing Temperature (Extruder) | 310° C (590° F) |

| Maximum Platform Temperature | 120° C (248° F) |

| Ambient Operation Temperature | 20-30° C (68-86° F) |

| Storage Temperature | 0-35° C (32-95° F) |

Weight and Physical dimensions

| Physical Dimension | 645 x 610 x 720 mm |

| Weight | 50 kg |

Electrical

| AC Input | Single Phase 220 V, 5 Amp. 50 Hz. |

| Maximum Power Consumption | 950 W |

Additional information

All information contained in this brochure and specification is subject to change without notice.